GRP stair nosings

PRODUCT CATEGORY

GRP Stair Nosings-AST1175

GRP stair nosings solutions have been specifically engineered to cater to the demands of high-stress environments.

These GRP stair nosings are ideally suited for deployment in critical applications such as emergency fire exit staircases, offshore oil platforms, and various heavy-duty industrial settings, where resilience and durability are paramount.

Crafted from superior quality fiberglass, Antislip Tech’s offerings exhibit exceptional resistance to a broad spectrum of chemicals, and they are characterized by their non-conductive properties, inherent fire retardancy, and imperviousness to high moisture levels, making them a preferred choice for robust surface-mounted stair edge protection.

Core Features

- Quality Raw Materials Long life

- Heavy Duty Coarse Grit coated Provides a consistent co-efficient of friction.

- Fiberglass step cover - Durable safety surface

- Fibreglass – ideal for industrial use

- Perfect for just about any structurally sound surface.

- Made to Order, 2 to 3 week lead time.

500+

Projects Served

200+

Unique Stair Nosing Molds

30+

Countries Shipped

7

Year of experience

01

Enduring and straightforward to apply to both pre-existing and newly constructed stair treads.

02

These units feature a durable, abrasive surface that not only enhances visual appeal through vibrant color options but also significantly mitigates the risk of slips and falls, thereby aligning with the stipulations of the Disability Discrimination Act (DDA), ensuring compliance with the Equality Act.

03

Each piece is precision-engineered with a beveled rear edge, a detail that augments overall safety and underscores our commitment to delivering products that combine functionality with a keen focus on user protection. This meticulous design consideration reflects our dedication to excellence in safety standards within the architectural and industrial sectors.

Product Attributes of GRP Stair Nosings

Product Customized of GRP Stair Nosings

Choose Your GRP Stair Nosings Color

Inform us the color you want, and we will design the GRP stair nosing for you.

We also can do Solid, 2 Tone, Glow-in-dark for you.

Choose the Grit of GRP Stair Nosings

1/8′ Heavy Duty fiberglass (plus thickness grade below)

- Super Fine (Barefoot) – .16′ / 4.1 mm. For boats, pools, showers

- Extra Fine (Residential) – .17′ / 4.3 mm. For residential applications deck steps, porches

- Fine (Commercial/Pedestrian) – .18′ / 4.6 mm. For bus steps, commercial buildings

- Coarse (Industrial) – .19′ / 4.8 mm. For most all industrial applications

- Extra Coarse (Offshore/Heavy Duty) – .26’/ 6.6 mm. Oil platforms, heavily soiled or wet areas

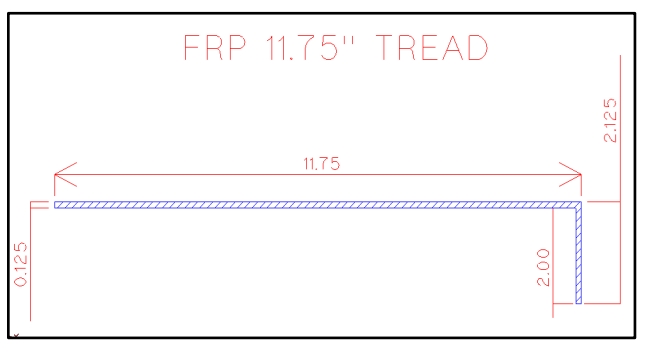

Do Your Own Size of GRP Stair Nosings

We can customize the size of GRP stair nosing for you.

Inform us your size, and we will give you the CAD design to conform.

Get to Know Advanced Manufacturing

ADVANCED FACILITIES

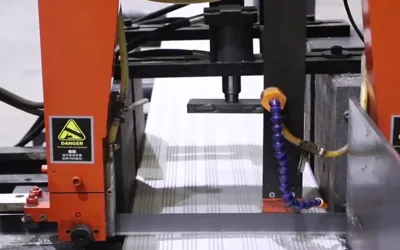

New & Advanced Equipment

Our factory is equipped with the latest machinery and equipment, as well as environmentally friendly technology. This allows us to produce high quality stair nosing products with high efficiency and low environmental impact.

Innovation in Stair Nosing

We are committed to providing our customers with the best possible products and the best possible service. To do this, we invest heavily in research and development. Our engineers are constantly working on new technologies to improve the quality, performance, and efficiency of our stair nosing.

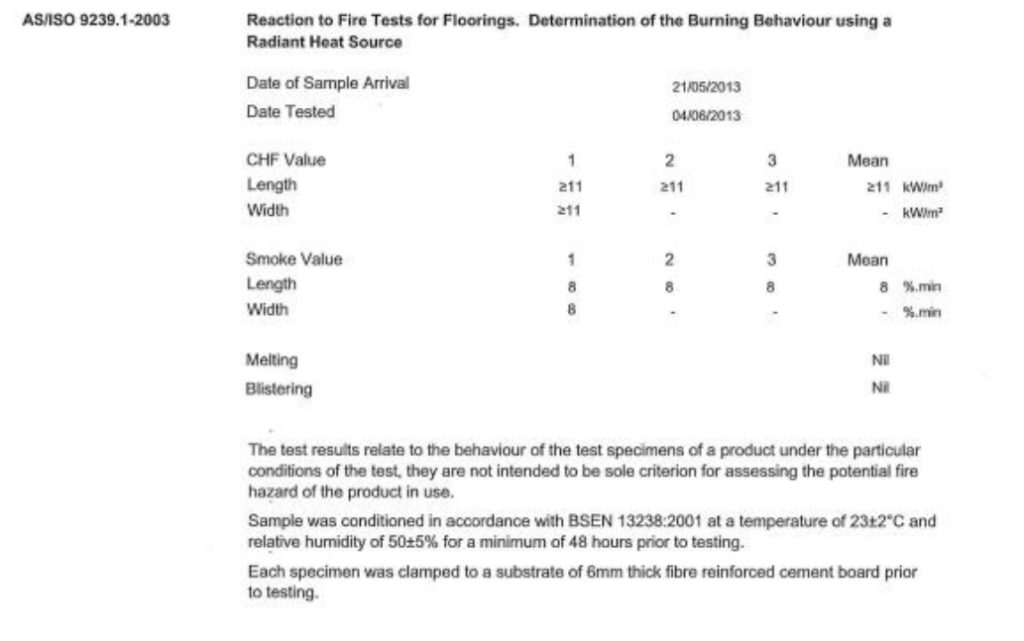

Test and Results of GRP Stair Nosings

Fire Radiant Report

- Pass the AS/ISO 9239.1-2003

- Can produce as your requirement.

- Can meet your project’s requirement.

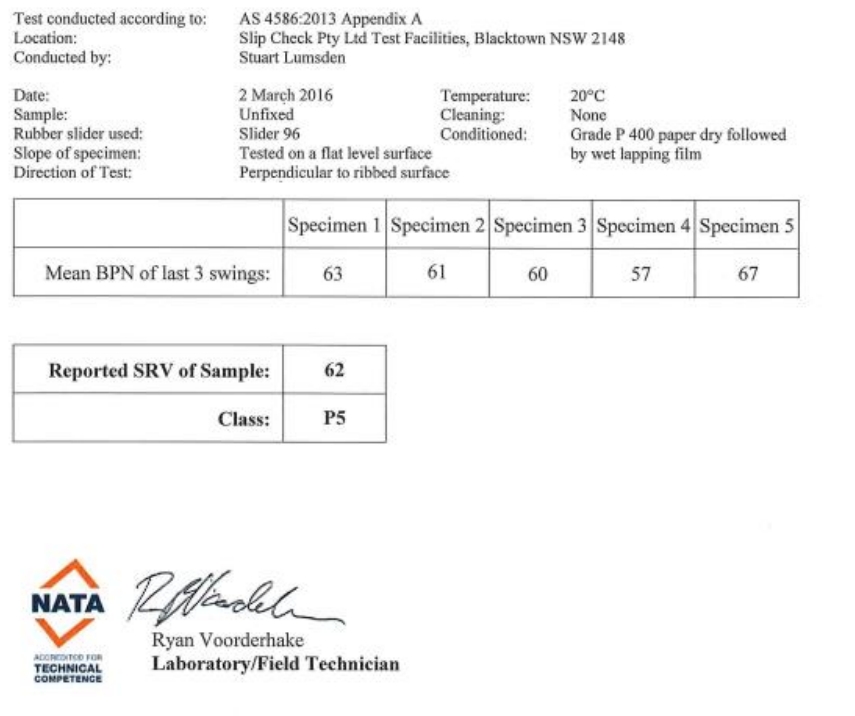

Anti-slip Report

- Anti-slip level: P5;

- Can produce as your requirement.

- Can meet your project’s requirement.

Other Test of GRP Stair Nosings

Mechanical Properties of GRP Stair Nosings

Where Client Satisfaction Shines

Expert Technical Assistance

Our team of skilled and dedicated technicians is available 24/7 to provide proactive and professional support, addressing your concerns regarding stair nosing quickly and effectively.

- Personalized Technical Assistance.

- Professional Design Support.

- Experienced Designers & Technicians.

Rigorous Quality Control

Adhering to our stringent quality control system, we prioritize the production of superior-quality stair nosing, ensuring that each item meets our standards of excellence

- ISO 9001 and 13485 Certified Facility.

- Stringent Manufacturing Standards.

- State-of-the-Art Facilities.

Extensive Product Range

With a wide selection of stair nosing options, we empower customers to find the perfect fit for diverse project requirements and design preferences.

- More than 300+ Molds

- Based on your project requirements, we provide professional recommendations.

- Free custom services as same as clients required

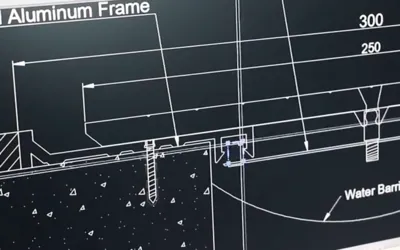

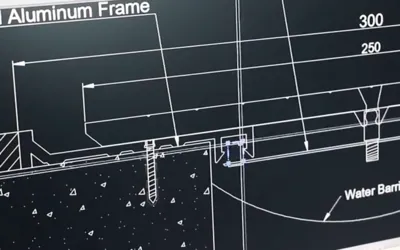

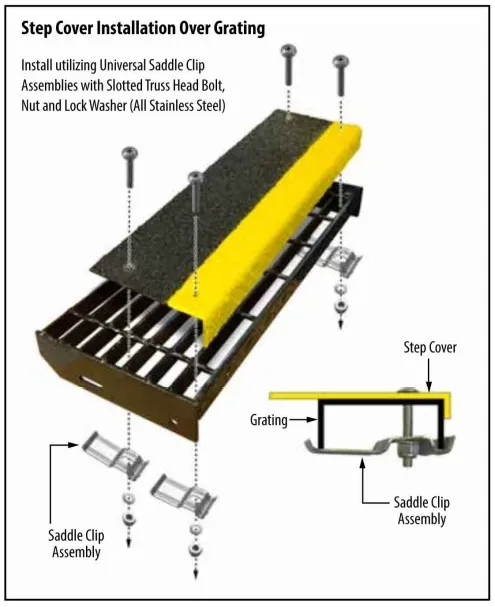

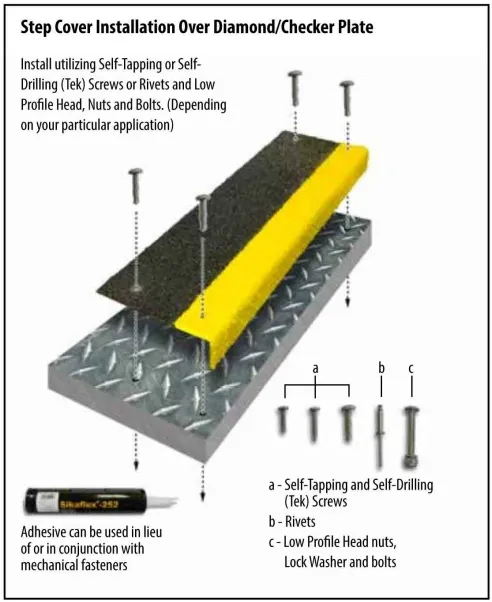

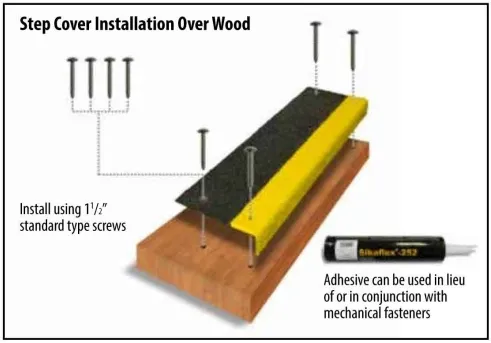

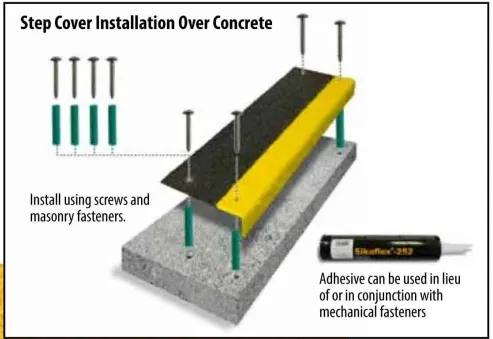

Installation Diagrams of GRP Stair Nosings

How to Clean & Maintain the GRP Stair Nosings

Cleaning

Routine maintenance is essential to ensure the optimal performance of Safety Covers by preventing the accumulation of debris. A variety of cleaning techniques commonly utilized in domestic and industrial settings are deemed suitable for this purpose. The application of detergents and mild degreasers can prove effective in the majority of cases. For the removal of persistent deposits, employing a brush with stiff bristles is advised. In industrial contexts, high-pressure heated water, a method often employed within the food processing industry, may also be implemented for cleaning purposes. It is crucial to exercise caution when selecting cleaning tools. The use of mops is strictly discouraged due to the risk of the Safety Cover’s abrasive surface retaining fibers from the mop, which can compromise its functionality. The utilization of solvents is generally not advised; however, if deemed necessary, it is imperative to use only mild solvents. These should be diluted and promptly rinsed off with copious amounts of water to prevent any potential damage to the cover’s surface.

Top Coating

For rejuvenating the color of worn stair nosings with a top coat, apply a minimal layer of alkyd silicone enamel. Excessive paint can compromise the anti-slip grit and lower the surface’s friction coefficient.

Snow and Ice Removal

- Avoid utilizing metal shovels, scrapers, and wire brushes for maintenance.

- Employ brooms to sweep away any loose snow.

- Opt for plastic shovels when clearing the upper layers of substantial snowfall.

- Apply salt, calcium chloride, or alternative ice-melting substances to treat compacted snow and ice.

Q: What is GRP Stair Nosings and What Makes It Special?

GRP, or Glass Reinforced Plastic, stair nosing is a durable edge protection designed for stairs. It’s special because it’s made from a composite material that’s strong, resistant to moisture and most chemicals, and it provides a high level of slip resistance, making it ideal for both indoor and outdoor applications.

Q: How Do I Install GRP Stair Nosings on My Existing Stairs?

Installing GRP stair nosings are typically straightforward. For surface-mounted applications, clean the stair edge, apply an appropriate adhesive, and then fix the nosing in place, ensuring it’s level and firmly bonded. Some GRP stair nosings may also be designed for slot-in or screw-down installation, following the manufacturer’s guidelines will ensure a secure fit.

Q: Can GRP Stair Nosings Be Painted or Customized to Match My Decor?

Yes, GRP stair nosings can be painted to suit your interior design. After ensuring the surface is clean and free of any contaminants, you can apply a coat of primer followed by your choice of paint. It’s important to use a paint that’s suitable for the material and to follow the paint manufacturer’s instructions for best results.

Keep in the Loop with AntislipTech

Antislip Academy

Explore insightful articles, tutorials, and expert tips on various antislip techniques, technologies, and trends.

Technical Guide

From details guides to tips, we cover a wide range of topics to help you navigate complex challenges.

Antislip Tech Blog

For valuable insights, expert advice, and inspiration for your antislip projects, check out our blog.

GET IN TOUCH

Let’s Get Your Business Started Today!

Take a journey of seamless communication and unparalleled collaboration, and contact us for innovative solutions, personalized service, and a partnership that sets you up for success.