Great things in business are never done by one person. They’re done by a team of people. We have that dynamic group of peoples

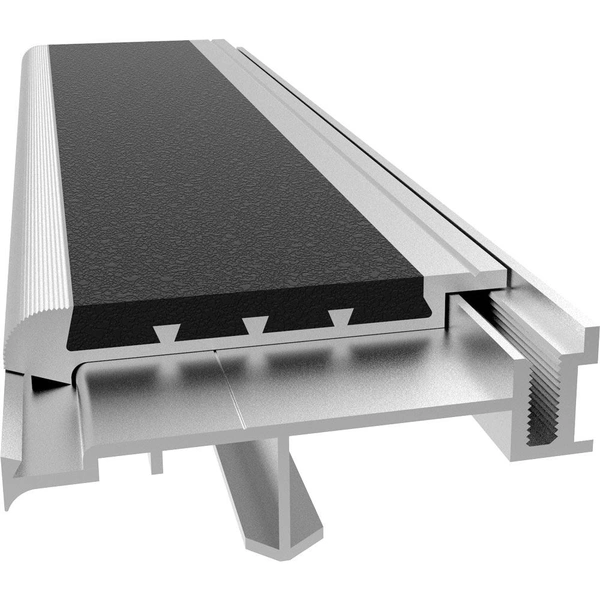

Anti-Slip Decking Strips/Step Strips

Ensuring safety in outdoor areas is crucial, and anti-slip decking strips play a significant role in this regard.

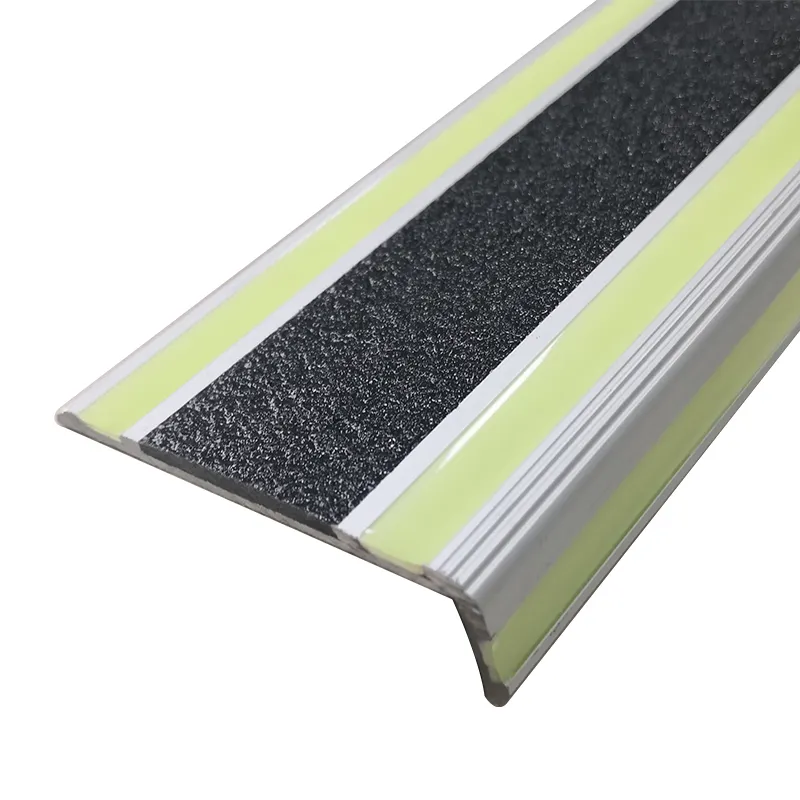

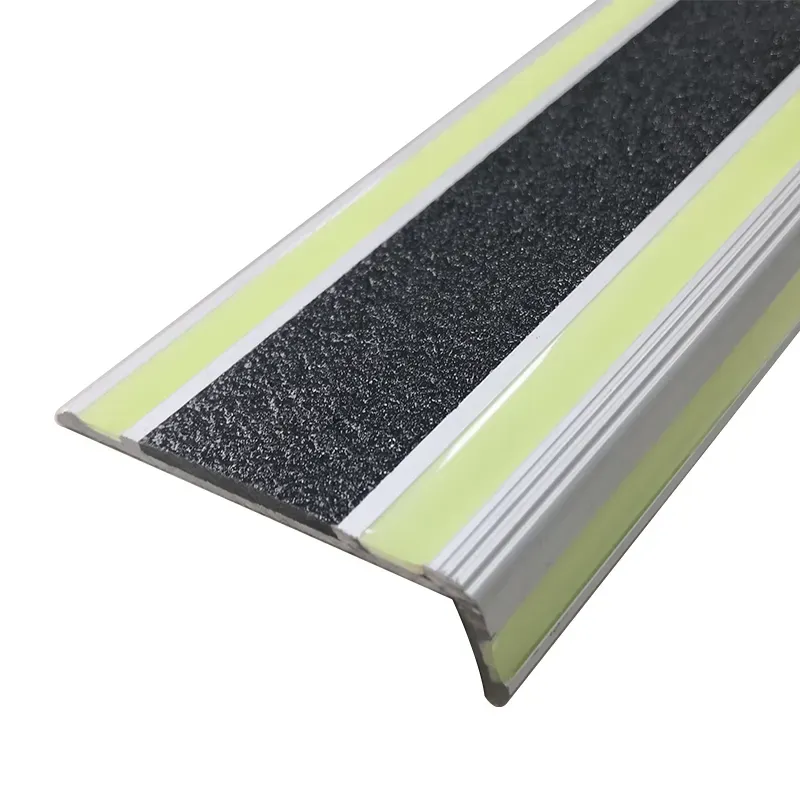

Why High Quality Stair Nosings Are Worth the Investment

Stair nosings are a vital component of any staircase, providing both a decorative touch and a critical safety feature.

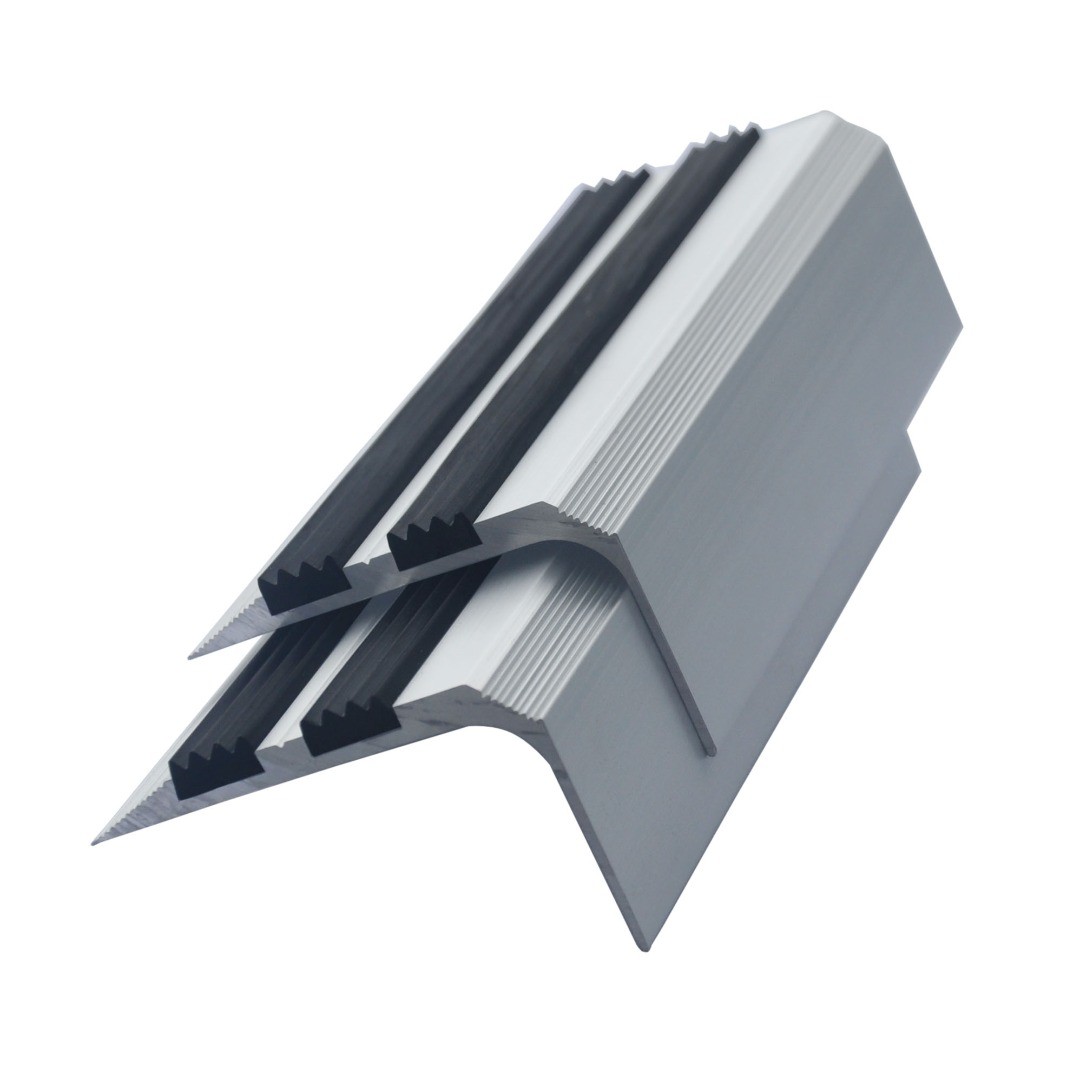

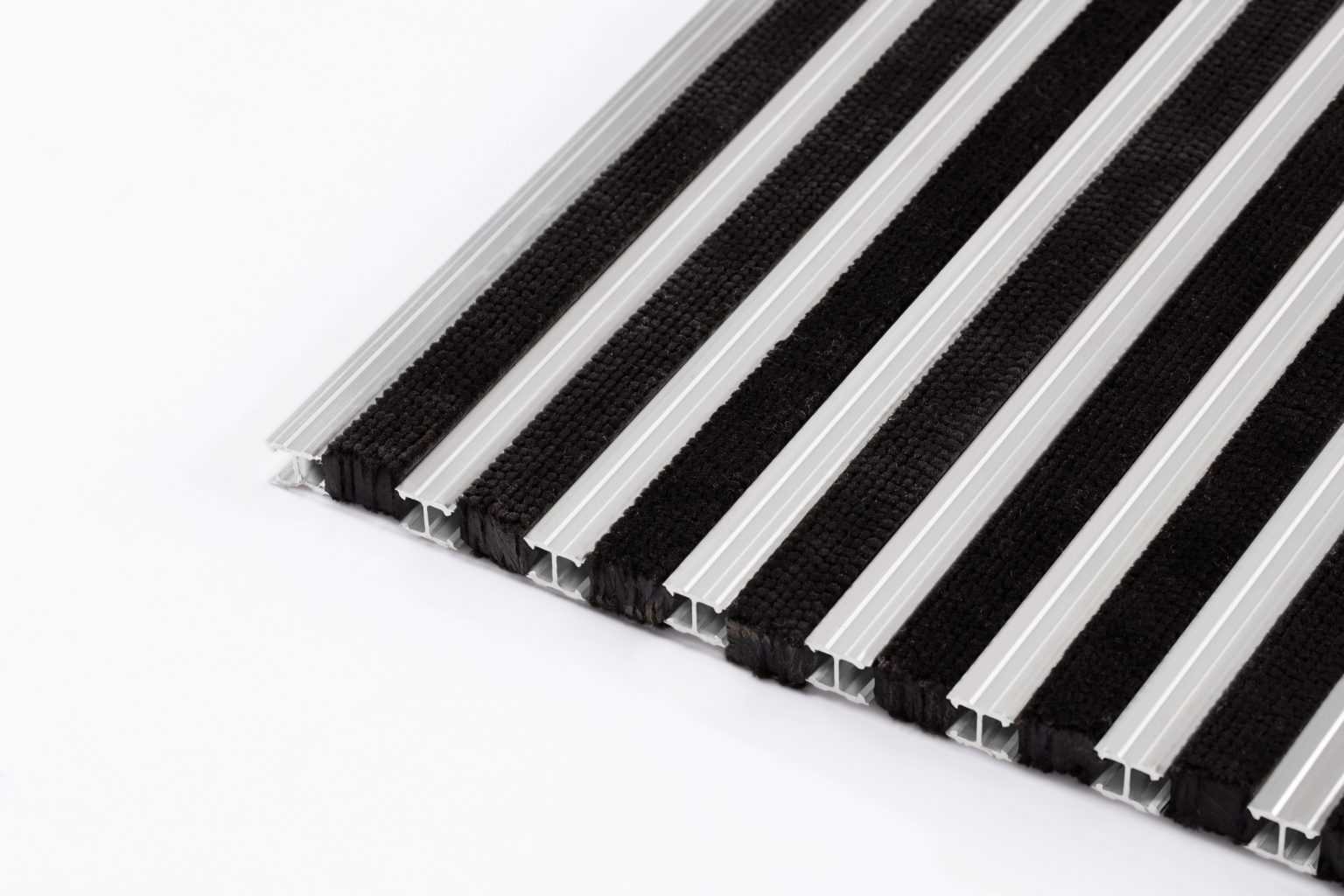

The Benefits of Aluminum Entrance Mattings for Schools and Educational Institutions

Discover how aluminum entrance matting in schools, enhances safety, cleanliness, and aesthetics, welcoming and secure environment for students and staff.