Great things in business are never done by one person. They’re done by a team of people. We have that dynamic group of peoples

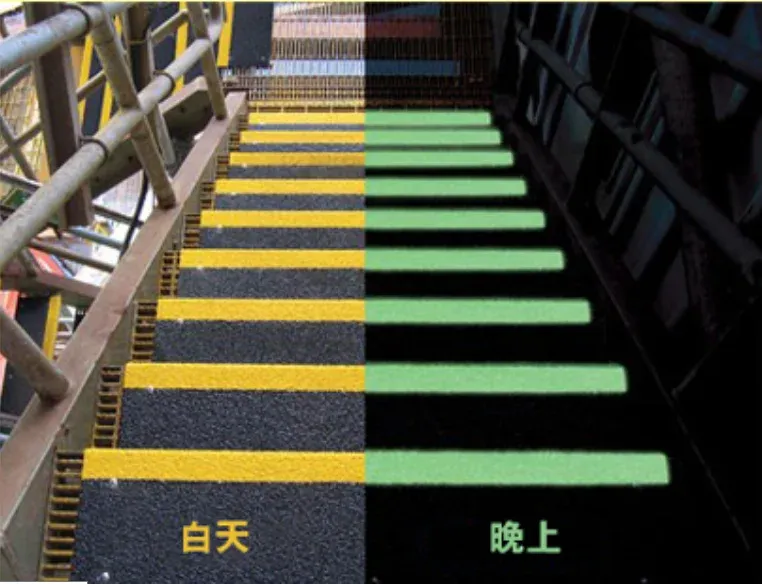

The Benefits of Anti-Slip Metal Strips for Homeowners

The Benefits of Anti-Slip Metal Strips for Homeowners: provide a practical and stylish solutions, enhancing safety by preventing slips and falls.

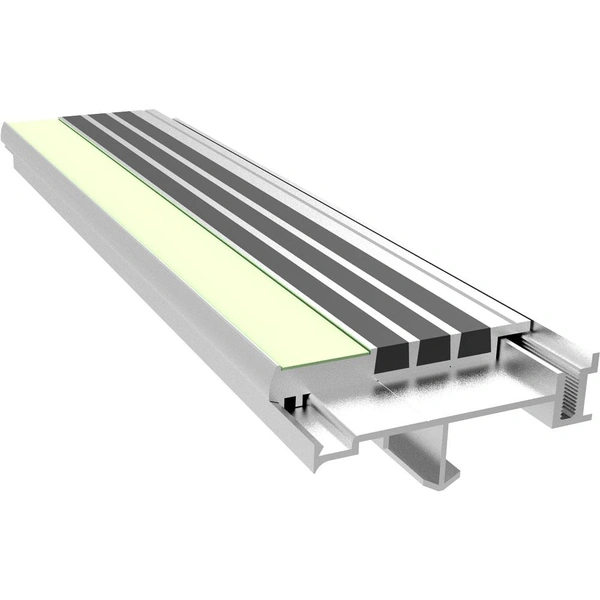

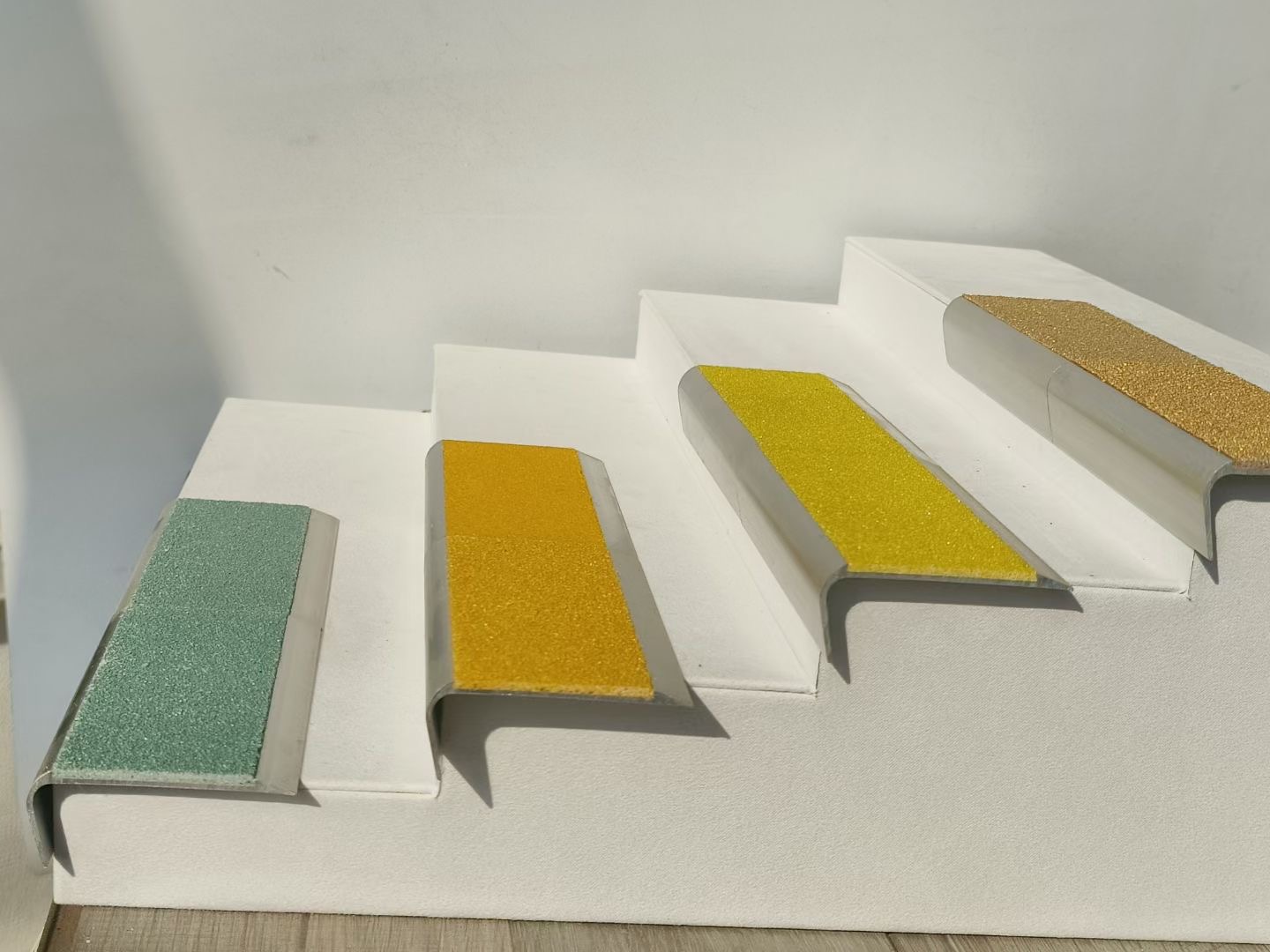

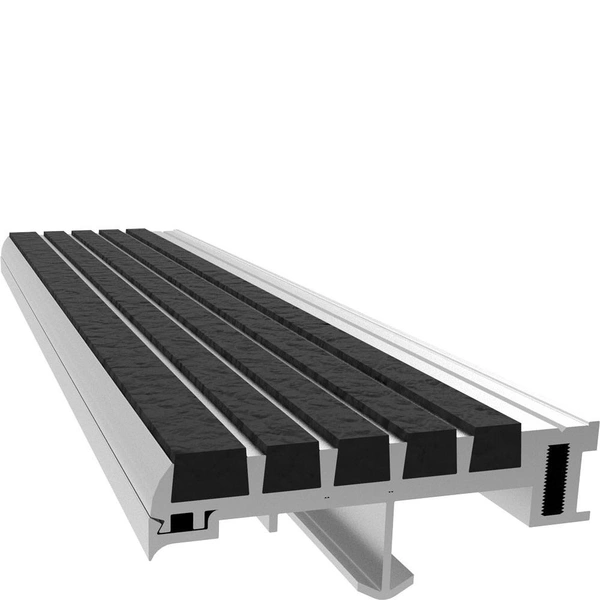

How to Choose the Right Aluminum Stair Nosing?

Aluminum stair nosings are essential components designed to enhance safety and durability in various settings by providing a non-slip surface at the edge of stair treads.

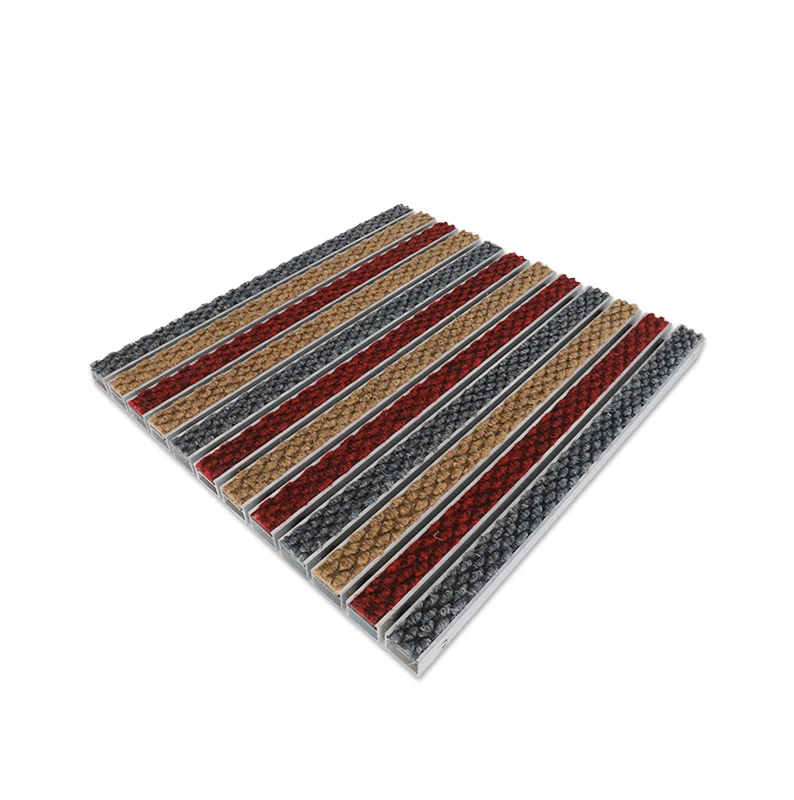

The Art of Balancing Functionality and Style in Stair Tread Design

Custom two-part stair treads balance functionality and style, offering ergonomic comfort, design flexibility, practical benefits, and diverse material options.